- sales@neptune-og.com

- +65 6250 3128

Turbine using biogas or gas or any liquid fuel

OPRA Turbines develops, manufactures, markets and maintains generator sets in the 2 MW power range using the OP16 series of gas turbines

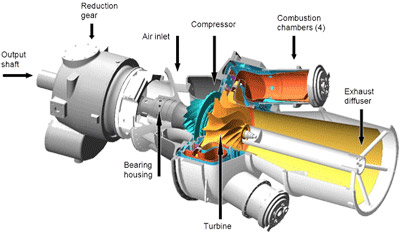

How our gas turbine work : After the gas has expanded through the turbine, the final expansion is provided by the exhaust diffuser, exiting at atmospheric pressure. The exhaust diffuser adds about 10% to the total output of the engine.

Following the expansion, the exhaust contains a large amount of energy. In the case of the OP 16 engine, the exhaust temperature is about 560 Celsius. This is a good temperature to raise steam for industrial processes. This process is called CHP (Combined Heat and Power) and is an important means to reduce overall fuel consumption and thereby CO2 emissions.

Utilising proven radial gas turbine technology, the OP16 gas turbine is a compact, efficient and reliable industrial gas turbine designed for supplying power generation applications to both the Oil and Gas and Industrial markets.

The OP16 generator sets can be provided in a variety of configurations and single or multiple units to meet customer specific requirements, from 2 MW to 10MW. The engineering design, component selection and maintenance accessibility of the generator sets enhance high reliability and long product life. The generator sets can be provided with low emission and dual / multifuel capabilities.

The OP16 generator sets can be provided in a variety of configurations and single or multiple units to meet customer specific requirements, from 2 MW to 10MW. The engineering design, component selection and maintenance accessibility of the generator sets enhance high reliability and long product life. The generator sets can be provided with low emission and dual / multifuel capabilities.

Download the data sheet or brochure for more information

1. OPRA Turbines Brochure English.pdf 2. Datasheet OP16.pdf

- Corporate View:Fullwidth View:Boxed